This is LESLIE SALT

| Leslie Salt Co. Refinery, Newark, California. |

|

In the control tower, high over the ship, you have just seen the signal to stop loading. Your companion, the loading superintendent, presses two control buttons and places a brief call to his crew chief. With satisfaction, he logs 15,000 tons; loading time: 22 hours...

A huge operations map occupies one entire wall of the large office of the Plant Manager. He has just shown us the workings of Leslie’s four integrated solar salt plants on San Francisco Bay. Employees: 400. Total area: 50,000 acres. Annual net evaporation: 150,000 acre feet. Average annual production: 1,200,000 tons…with additional facilities on the Great Salt Lake, Utah, and at Amboy, California.

Dropping by the order desk, it is apparent sales have been active and the customers receptive. Cars loaded today: 63. Thousands upon thousands of cases, bales, bags, blocks and bricks from the refinery, and from the stacks, huge volumes of raw salt for domestic and foreign industry.

Similar glimpses in any of a dozen departments would tell the visitor about the same story. From the chemistry lab to the President’s office, from accounting to Technical Service, supplying low-cost salt of the highest quality is a long-standing tradition with the entire Leslie organization. Add to that fifty years experience in all phases of salt usage, and we can proudly say—This is Leslie Salt.

|

Above: Extensive bird life addds much

interest to the marsh. |

THE STORY OF SALT For as many centuries as history has been recorded, man has evaporated sea water for salt. Without it, neither man nor animal survives for long. This vital mineral does a job in agriculture, industry and chemistry, which challenges the imagination. In the Western States, Leslie Salt is literally everywhere and has a hand in almost everything.

Salt cures hides, packs fish, seasons hay, feeds livestock, makes brines, preserves vegetables, cures meats, flavors breads and helps in softening water. It goes into soaps, dyes, drugs, plastics, textiles, pottery and synthetic rubber. A very substantial part of the Pacific Coast’s heavy chemicals are made from salt, and, in addition, it figures prominently in petroleum recovery, refrigera-tion and metallurgy.

Wherever the wheels of industry spin, the chances are you’ll find salt doing something useful. And it means a lot of salt must come from somewhere.

While this, then, is the story of salt, it is particularly the story of Leslie Salt and its unique role in a vital industry.

|

|

On the shores of San Francisco Bay, Leslie Salt Company has developed the world’s largest solar-

evaporation plant for the production of salt. By a system of levees, seawater is circulated through

shallow ponds, some of them 800 acres in size. |

Raw material. Handling billions of gallons

of seawater often produces interesting

patterns for the photographer. |

|

HARVESTING The San Francisco Bay Area is ideally suited to the economical production of salt from the sea by solar evaporation. Vast marsh areas on the distant fringes of the Bay make it one of the world’s finest locations - an unsurpassed natural resource centrally located in a fast-growing market.

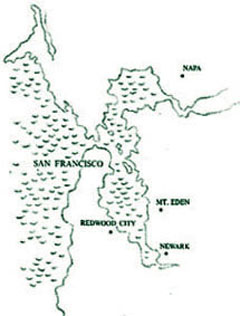

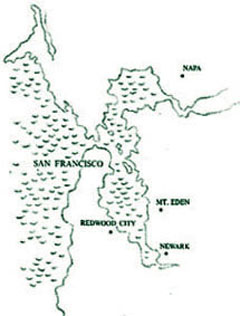

The map to the left shows approximately the location of the four major Leslie crude salt plants. Each operation is complete with respect to evaporating and crystallizing areas, together with extensive harvesting and stacking facilities.

|

The San Francisco Bay Area has produced salt

continuously for one hundred years. The scale

here is approximately 20 miles to the inch. |

Mountains of Leslie's solar-evaporated salt tower above the shores of San Francisco Bay.

In the background, typical crystallizing ponds. |

|

Mountains of Leslie's solar-evaporated salt tower above the shores of San Francisco Bay.

In the background, typical crystallizing ponds. |

With production headquarters in Newark, Alameda County, Leslie Salt operates approximately 50,000 acres of concentrating ponds through which salt water from the ocean flows in a never-ending cycle. The function of these ponds, through evaporation, is to increase the salinity of the slowly-flowing brine to the point where salt will crystallize. At this point, the heavy, reddish brine is transferred to crystallizing ponds where the winds and heat ofsummer finish theevaporating job and deposit salt crystals in a five-inch layer.

The salt is now ready for harvest. In late September each year, huge harvesters go to work night and day in the crystallizing ponds, loading salt into the washing plants. Operating six harvesters, Leslie is able to stockpile over 20,000 tons daily of crude salt about 99 percent pure.

Toward the end of December, the harvest is finished, and the vast stockpiles become a familiar sight to anyone traveling in the area— both on land and by air.

The speed and magnitude of the salt harvest, with its track, tracklayers, dump cars, motive power and the harvester itself, owes much of its efficiency to Leslie’s engineering staff—trained experts who are constantly at work improving these operations.

Huge mechanical harvesters scoop up the crystallized salt and load it on trains,

which shuttle back and forth across the ponds to the washing shed. |

|

SALT FROM THE SUN AND THE SEA

|

This harvester, one of six designed by Leslie engineers, picks up the crude salt from the

pond bottoms and loads the mall rail cars strung out behind the locomotive. From here

the salt goes to the wash house (where it is washed four separate times with saturated brine).

It then is piled on the stack to drain. |

This four-inch cluster of salt crystals is typical of those found on the bottom

of the salt ponds when they are drained in the Fall. This crude salt, because of

Leslie’s controlled crystallization process, is 99.6 per cent pure sodium chloride. |

|

SALT - a necessity of life

Crew work round the clock once the harvest starts to get the "crop" in ahead of the winter rains.

Crude salt right off the stack or roughly graded as to size is used in pickling, refrigeration, hide curing, chemicals and many other industries.

Kiln dried salt, with a purity of 99.7 per cent, is crude salt that has been washed and then dried in a rotary kiln at 365º F. Some uses for the coarser grades are in livestock feeding, to regenerate water softeners and in some food industries. The finer grades are used primarily in animal feed mixes. |

|

SALT - vital in Food Porcessing

|

Vacuum refined salt is made by dissolving crude salt and then recrystallizing the treated brine in huge vacuum "pans." With a purity of 99.99 per cent, it is ideally suited for use in foods. All of the foods shown below have required salt either in their making or seasoning.

Automatic dispensing of salt is a must on high speed canning lines. The Salter Machine, shown above, is salting cans of green beans. Leslie Salt tables also are available for machine dispensing.

Cans move down the line at the West Coast tomato cannery. Half of the tomatoes canned in the United States are processed in California, most of them with Leslie Salt. Both granular and tablet products are being dispensed in the tomato line. |

SALT - for Animal Feeding

|

|

Livestock need salt just as humans do - as

a seasoning and as a vital factor in growth, health

and reproduction. |

Thousand of tons of salt are used annually in feed mixes

for livestock and dairy herds. Salt, in block and loose form,

also serves as a carrier for major and trace minerals and for

antibiotics. On the range, it can regulate protein intake

and promote uniform grazing. |

SALT - vital in Industry

|

Without salt, there would be no

water softening as we know it. Salt brine is needed to regenerate

the spent ion exchange resins and permit their reuse, Industrial

installation in hospitals, laundries, hotels and canneries have

kept pace with the increase in home water softening units.

The last thing an oilman hopes for from his oil well is salt, but

it’s often one of the first things used in sinking a well. Salt

in the drilling mud prevents cavities from forming in salt

layers through which the well passes. |

Bulk loading of undried grades of salt, by truck or rail,

is handled efficiently from these large bins located at

Leslie’s California plant. Bulk shipments of kiln dried

and vacuum grades can be made by rail.

Hundreds of thousands of tons of salt move annually

from Leslie’s stockpiles to chemical firms producing

sodium and chlorine compounds. Shown above is one

of the huge brine vats used by the electrochemical industry.

This brine is subjected to an electric current that separates

the salt into its components, sodium and chlorine.

The uniformly high quality of Leslie’s product is a result

of the constant analyses made through every step

of production. In the quality control laboratory (at right),

chemists and technicians carry out this continuous testing program.

|

|

LESLIE... first in salt. With three major purity grades, 20 different screen sizes and "specialty salts" featuring a score of additives, Leslie can give you the salt you need.

Just as important, you will find the service you need and demand at Leslie Salt Co.

Your Leslie representative is a salt specialist. He can answer your questions about the grade of salt for you to use. He can counsel you on the type of packaging, the additives best suited to your needs, the most economical method of delivery, and how best to handle or brine salt.

Because salt is used in such a variety of industries, Leslie representatives quickly build up a fund of knowledge about the techniques of salt use and salt handling. For background information, specialized knowledge and testing they refer to Leslie’s Technical Service Department and laboratory, staffed by engineers and chemists trained in the problems of salt processing and handling.

There’s a Leslie representative in your area. Please call him for your salt needs.

DISTRICT OFFICES

San Francisco: 505 Beach Street—PRospect 6-5730

Los Angeles: 920 Leslie St., La Habra—M Adison 6-0528

Seattle. Pier: 66, Bell Street Terminal—M Ain 3-2273

Portland: 912 N.E. 25th Street—B Elmont 4-7231

Salt Lake City: 178 West 3rd South—E Lgin 5-7401

Vancouver, B.C.: 85 West First Ave.—T Rinity 4-3471

(Vancouver Salt Company, Limited)

…for salt tablets and service

Scientific Salting Company of California, Newark

S Y camore 7-1820

…for salt dispensers and service

Salter Machine Co., 2016 Clement Ave., Alameda

LA kehurst 3-6191

…for Technical Service

Leslie Salt Co., 505 Beach Street, San Francisco

PRospect 6-5730

LESLIE SALT CO.

…first in Service

|

|

|

These livestock salt blocks are some of the 170 separate,

standard salt items handled by the Leslie Salt Co.

Mechanization and speed are stressed in this warehouse,

one of the industry’s largest. |

PROCESSING During the year, salt is withdrawn from the stock-piles for shipment or further processing. A large percent of this salt is shipped "as is" for manufacturing. Huge quantities are rewashed, screened and bagged for refrigeration, fish packing and brining operations, among other uses. Tens of thousands of tons are kiln-dried, milled, screened, and bagged for dozens of uses ranging through many phases of stock-feeding, industrial processing, water softening and the like.

But the finest grades of salt, known generally as vacuum salt, and destined largely for human consumption, are processed in an entirely different way. The crude salt from the stockpile is redissolved to produce a brine which is treated and tested for purity. This brine is then fed into vacuum evaporators in the refinery which remove most of the water. The salt is then dried at high temperature, cooled, and conveyed through a screening operation prior to being placed in storage bins for inspection and packing. The result is the fine-grained salt of the type so familiar to the millions of users of the Leslie table salt package.

In addition to its use in the home, this product has wide application in the dairy, baking, canning and meat packing industries, to name a few.

Other grades include the salt tablet (for high speed salting of canned goods as they are processed) and blocks, bricks and petlicks for animal feed.

An important by-product of Leslie’s salt-making process is the mineral-rich brine remaining after salt has been removed. Termed bittern, it provides raw material for the production of magnesium compounds and bromine.

FLOW CHART - from salt water to processed sat for home and industry.

SALT FOR INDUSTRY A century ago salt was commonly measured by the bushel and its principal applications centered on food—both flavoring and preserving. While our food processing industry has grown to giant proportions, with a comparable increase in the need for salt, other industrial uses for salt have diversified tremendously.

In the field of chemicals, as well as in water softening, road stabilization, and textiles, salt plays an increasingly large part. These relatively newer uses are, of course, in addition to well-established and large users such as feed dealers, feed mixers, metals and petroleum.

As a measure of its importance in modern industrial countries, the consumption of salt ranges up to 250 pounds per person per year when all uses are taken into consideration. Refinements in salt-using processes have continually demanded improved methods of handling and servicing. It is in these areas that Leslie Salt, the West’s largest salt producer and the world’s largest solar salt operation, has earned its reputation as the leading Pacific Coast supplier of every type of salt product.

Whether the requirement is for a small supply of tablets, a season’s requirements for refined salt in a tightly-scheduled plant, or a million tons of bulk crude salt for delivery over a period of years, the name Leslie is positive assurance of continued satisfaction in salt products and service.

Handling huge volumes of salt is a job for specialized equipment, much of it designed specifically for the purpose, with a view to utmost reliability. Constant progress to insure prompt handling and delivery of the product at optimum specifications is achieved. One example of this is the Leslie deep water terminal at Redwood City for the loading of vessels carrying up to 15,000 tons of bulk crude salt. Delivery to the ship is accomplished at the rate of 700 tons per hour, which assures customers using this service of dramatically reduced layover time and attendant expense. |

|

SALT AND THE CONSUMER To the housewife shopping the super market, salt is an item bought with pennies. To the rancher with grazing cattle, salt is a fifty-pound block necessary to the health of his stock. To the buyer at a food processing plant, salt is a carload which must roll in on schedule. To the electrochemical plant, producer of endless products from salt, it is basic to the entire operation.

Salt is many things to many people. Leslie Salt is proud of the part it plays in supplying this vital mineral for the hundreds of purposes which only salt can serve. Knowing that thousands of buyers and millions of homemakers look to Leslie today for their requirements in salt is a source of very great satisfaction. Meeting these requirements, and planning now to meet even greater requirements in the future, is a constant challenge . . . But a challenge we gladly accept to build even further confidence in our products and services.

Working as a neighbor and citizen in many communities, and as a manu-facturer in several, the Leslie organization is constantly seeking better ways to handle our very substantial assignment. In this way, it seems to us, we best serve our many friends, and in particular, we hope, all consumers of salt.

|

|

|